Pneumatic cylinders have been on the market for many decades, providing efficiency in industries such as manufacturing, construction as well as in logistics. With development in technology, new designs and variants of the pneumatic cylinders are being developed making it reliable, hardwearing, and flexible. This article brings out some of the current and emerging pneumatic cylinder trends and innovations specifically targeting business-to-business organizations in a bid to improve on performance. As we have seen earlier, a multitude of material developments are used in pneumatic cylinders but nowadays numerous new exciting developments can be seen in the double-acting designs.

Advancements in Cylinder Materials

The selection of materials used in pneumatic cylinders has always been an important factor although recent development has opened up shifts. It is a fact that advanced high-performance materials and compounds are gradually replacing conventional metals such as steel and aluminum. These new materials offer several advantages: These are useful in that they are; light in weight, mechanically strong, and do not corrode easily. It means that the durability of the pneumatic cylinders has been enhanced and on the other end, the frequency of maintenance and service is less. Manufacturers and suppliers of the pneumatic cylinder are now providing a large variety of options where customers can select cylinders that are environmentally friendly, those that can sustain heavy load, or those that are resistant to wear and tear.

For example, some of the manufacturers have developed cylinders that are made from advanced polymer composites. They possess properties like strength of metals but with the special feature of being corrosive free. This development is particularly useful for industries that fully expose the cylinders to the environment such as the food processing industries or the chemical industries.

Smart Cylinders with IoT Integration

The advanced technologies such as the Internet of Things (IoT) has affected so many industrial systems and pneumatic cylinders are not exempted. Advanced pneumatic cylinders are now IoT compatible and allow control and maintenance through preventive checkups. Such innovations make businesses have better control of their equipment, they are able to monitor their performance, see signs of developing faults and even schedule for repairs to prevent this from happening.

Essentially for companies that use large machinery, for firms in the automotive or packaging sectors, smart pneumatic cylinders could lower the losses significantly. Existing suppliers of double-acting pneumatic cylinders now provide smart cylinder models that are fitted with sensors, feedback, and data processing systems. These features can give insight into the organization’s performance that leads to improvement in decision making as well as use of resources.

Compact and Customizable Designs

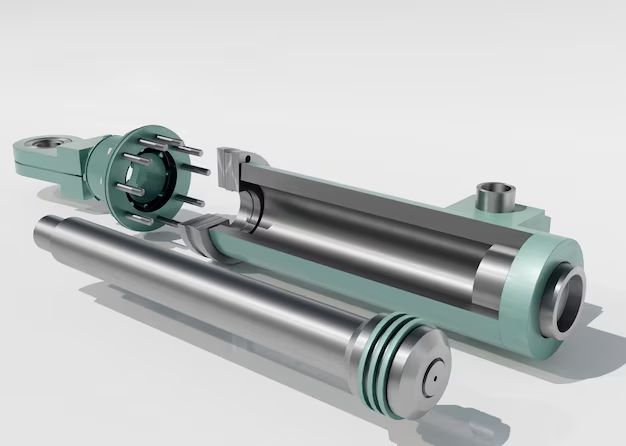

Another emerging trend, which seems very obvious in pneumatic cylinder development is towards compact cylinders with a high degree of customization. Pneumatic cylinders have been in use for several decades and as industries harmonize on space and efficiency in the machines, the smaller and more adaptable pneumatic cylinder has become ideal. Miniature actuators can do so in narrow spaces while achieving good force levels, they can be used in robotics, in medical equipment, and in automation of assembly lines.

Another emerging trend is that industries now need pneumatic cylinders to be more customized. The features that can be specified by suppliers today include; stroke length, diameter, material and mounting configuration among others. This versatility means that accurate and compatible products can be supplied to the business organizations without any compromise.

Enhanced Energy Efficiency

As sustainability is now a focus of many industries, energy saving pneumatic cylinders are more or less the topic of today. This was done by ensuring that manufacturers design their cylinders to be able to provide the same or higher power output with less air consumption. Not only does it cut on the expenditure on energy for the businesses which in turn aids them in lowering their environmental impact.

One advancement made in this area is the designing of what is known as air-saving circuits which help to minimize air use by the circuits by circulating the compressed air being used in the system. Pneumatic cylinder suppliers are also coming up with cylinder models with low friction seals that require efforts to push the piston and minimize energy usage. These developments are highly relevant in industries with many operational cycles, so they do not cease at night, for example in material handling or food processing industries.

Improved Seals and Durability

The subject where most of the attention has been paid is making the seals of pneumatic cylinders better. Seals are important to reduce the leakage and enhance the overall operation of the machinery but the seals are susceptible to wearout along with the passage of time. Advancements in seals which have resulted in the development of new designs of the pneumatic cylinders ensures that they are longer lasting and of more durability.

Currently manufacturers are providing cylinders with self lubricating seals which will require very minimal maintenance. Also, the increased understanding of seal technology has enhanced the technical parameters of the double acting pneumatic cylinders. The suppliers of double-acting pneumatic cylinders are incorporating new sealing systems thereby reducing leakages of air within the cylinder and increasing the lifespan of the cylinder. Some of these improvements are specifically advantageous for the companies functioning in the severe climates and/or industries using large equipment.

The industry of pneumatic cylinders is currently experiencing exciting innovations that have a significant way of impacting how organizations think about automation and improvement. From the application of the new material to IoT, above advancements are helping companies to arrive at more resilient, effective, and adaptable solutions. If one wants to avoid congestion, cut on energy consumption, or look for small cylinders to suit specific uses, then the advanced models of pneumatic cylinders come with the following advantages. Due to the constant improvements in the products, pneumatic cylinder suppliers and double acting pneumatic cylinder suppliers are in the perfect time to test out different options for their industrial users.

Thus, they sum it up that pneumatic cylinders will always be in focus in such automotive industries as it offers tremendous scope of boosting productivity and envisaging a stringently innovative future.