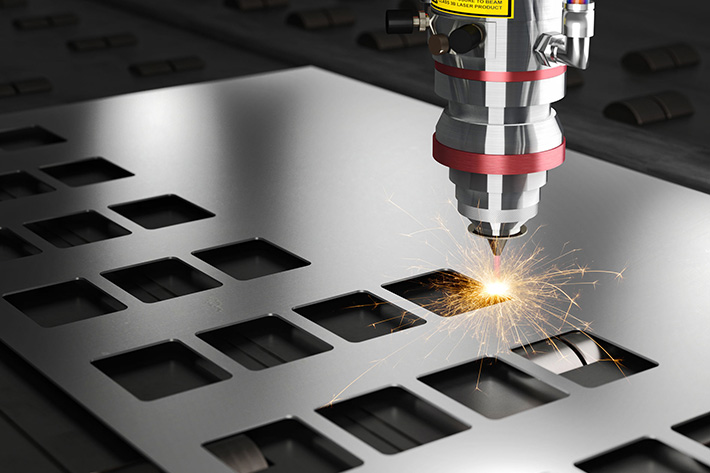

Metal laser cutters have revolutionized the manufacturing industry, offering precision, efficiency, and versatility that is unmatched by traditional cutting methods. As technology continues to advance, these powerful tools have become indispensable in various sectors, from automotive and aerospace to construction and jewelry making. In this blog, we will explore the numerous advantages of using a metal laser cutter and why it has become the preferred choice for many businesses.

Unmatched Precision and Accuracy

One of the most significant advantages of a metal laser cutter is its unparalleled precision and accuracy. Laser cutters can achieve incredibly tight tolerances, often within a few micrometers. This level of precision is crucial in industries where even the slightest deviation can result in significant issues, such as in the aerospace and medical device sectors.

The precision of a metal laser cutter is due to its ability to focus a high-energy laser beam onto a very small spot. This focused beam allows for clean, sharp cuts with minimal material wastage. Additionally, advanced CNC (Computer Numerical Control) systems enable precise control over the cutting process, ensuring consistent and repeatable results.

Versatility in Cutting Various Metals

Metal laser cutters are incredibly versatile and can cut a wide range of metals, including steel, aluminum, brass, copper, and titanium. This versatility makes them suitable for diverse applications across different industries. Whether you need to cut thin sheets or thick plates, a metal laser cutter can handle the job with ease.

Furthermore, laser cutters can be adjusted to accommodate different metal types and thicknesses. By altering the laser’s power and speed, operators can achieve optimal cutting conditions for each material, ensuring high-quality results every time.

High Speed and Efficiency

Speed is another significant advantage of using a metal laser cutter. Laser cutting is much faster than traditional methods, such as mechanical cutting or sawing. This increased speed translates to higher productivity and shorter lead times, which is essential in today’s fast-paced manufacturing environment.

The high-speed cutting capability of laser cutters is particularly beneficial for large-scale production runs. Businesses can complete more projects in less time, increasing their overall output and profitability.

Clean and Smooth Edges

Metal laser cutters produce clean and smooth edges, reducing the need for secondary finishing processes. Traditional cutting methods often leave rough or jagged edges that require additional grinding or polishing. In contrast, laser cutting results in minimal burrs and a high-quality finish.

This clean-cutting capability is especially important in industries where aesthetics and surface quality are crucial, such as in the production of consumer electronics or decorative metalwork. The smooth edges produced by laser cutting enhance the overall appearance and quality of the final product.

Minimal Material Waste

Efficient material utilization is a key advantage of metal laser cutters. The precision of laser cutting ensures that there is minimal material wastage, which can significantly reduce production costs. Traditional cutting methods often result in larger amounts of scrap metal, which can be expensive to dispose of and detrimental to the environment.

Laser cutters use a focused beam that cuts through the material with minimal kerf (width of the cut), maximizing the usable material. This efficiency is particularly beneficial when working with expensive metals, where every bit of material saved translates to cost savings.

Reduced Risk of Material Deformation

Heat distortion is a common issue with traditional cutting methods, especially when working with thin or delicate metals. The concentrated heat generated by mechanical cutting tools can cause the material to warp or deform, compromising its structural integrity.

Metal laser cutters mitigate this risk by using a highly focused laser beam that generates minimal heat in the surrounding areas. This localized heating reduces the chances of material deformation, ensuring that the cut pieces maintain their original shape and dimensions.

Automation and Integration with Modern Manufacturing

Another significant advantage of metal laser cutters is the integration of automation and advanced control systems. Modern laser cutting machines are equipped with CNC systems that allow for precise control over the cutting process. These systems can be programmed to execute complex cutting patterns with high accuracy, reducing the need for manual intervention.

Automation also facilitates seamless integration with other manufacturing processes. For instance, laser cutters can be combined with robotic arms for automated material loading and unloading, further increasing efficiency and reducing labor costs.

Flexibility in Design and Customization

Metal laser cutters offer unmatched flexibility in design and customization. The precision and control provided by CNC systems enable the creation of intricate and complex shapes that would be challenging or impossible to achieve with traditional cutting methods.

This design flexibility is particularly valuable in industries that require customized or bespoke products, such as in the fashion or interior design sectors. Laser cutters can quickly and accurately produce unique patterns and designs, allowing businesses to offer personalized solutions to their customers.

Safety and Reduced Risk of Accidents

Safety is a paramount concern in any manufacturing environment. Metal laser cutters offer several safety advantages over traditional cutting methods. The enclosed cutting area of laser machines minimizes the risk of accidental contact with the cutting tool, reducing the likelihood of injuries.

Additionally, laser cutters produce minimal dust and debris compared to mechanical cutting methods, improving the overall cleanliness and safety of the workspace. Many modern laser cutting machines are also equipped with advanced safety features, such as automatic shut-off mechanisms and protective barriers, further enhancing operator safety.

Environmental Benefits

Sustainability and environmental responsibility are increasingly important considerations for businesses. Metal laser cutters offer several environmental benefits that align with these goals. The precision and efficiency of laser cutting result in less material wastage, reducing the amount of scrap metal that needs to be disposed of.

Moreover, laser cutting is a dry process that does not require the use of cutting fluids or lubricants, which can be harmful to the environment. The reduced need for secondary finishing processes, such as grinding or polishing, also minimizes the generation of dust and particulate matter.

Conclusion

In summary, the advantages of a metal laser cutter are numerous and significant. From unmatched precision and versatility to high speed and efficiency, metal laser cutters offer a range of benefits that make them the preferred choice for many industries. The ability to produce clean, smooth edges with minimal material waste, reduced risk of material deformation, and enhanced safety further solidify their position as a superior cutting technology.

As technology continues to evolve, metal laser cutters will likely become even more advanced, offering new possibilities and opportunities for businesses. Whether you are in the automotive, aerospace, construction, or any other industry that requires precise and efficient metal cutting, investing in a metal laser cutter can provide a substantial competitive advantage. Embrace the future of cutting technology and experience the transformative benefits of a metal laser cutter for your business.