Introduction to Sludge Dewatering Equipment

Sludge dewatering equipment plays a crucial role in modern wastewater treatment. As industries grow, so does the volume of sludge generated. This can pose significant challenges if not managed correctly. The right equipment can transform this thick, messy byproduct into something more manageable and less harmful to the environment.

But with numerous options available on the market today, how do you choose? From advanced technology to varying capacities, understanding your specific needs is vital before making a purchase. Whether you’re an industry veteran or just starting out in wastewater management, knowing what to look for will ensure you invest wisely in efficient and effective solutions that stand up to rigorous demands.

Let’s dive deeper into the world of sludge dewatering equipment and explore everything you need to consider before hitting that buy button!

Types of Sludge Dewatering Equipment

Sludge dewatering equipment comes in various types, each designed to tackle specific challenges. One common type is the centrifuge. This device uses rapid rotation to separate solids from liquids effectively.

Belt filter presses are another popular option. They work by passing sludge between two porous belts, allowing water to drain away while retaining the solids.

For a more chemical approach, you have vacuum filters. These utilize suction to pull moisture out of sludge, resulting in drier cakes.

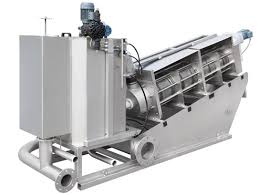

Then there are screw presses that combine mechanical force and gravity for efficient dewatering. Their compact design makes them suitable for smaller spaces.

Plate-and-frame filters offer versatility and ease of maintenance. They can handle varying sludge compositions without sacrificing performance.

Choosing the right type depends on factors like the nature of your sludge and operational requirements.

Factors to Consider Before Buying

When investing in sludge dewatering equipment, consider capacity and efficiency first. You need a system that can handle your facility’s specific volume and type of sludge efficiently.

Next, look at the technology being utilized. Advanced automation equipment can enhance performance and reduce labor costs significantly. It’s worth exploring options with innovative features like real-time monitoring.

Maintenance should also be on your radar. Understand the operating costs associated with upkeep to avoid unexpected expenses down the line.

Think about environmental impact. Choose equipment designed for sustainability to minimize waste disposal issues and comply with regulations while enhancing your company’s green image. Each factor plays a role in ensuring you make an informed decision tailored to your needs.

A. Capacity and Efficiency

When selecting sludge dewatering equipment, capacity and efficiency are paramount. The ability to process large volumes of sludge without compromising quality is crucial for operations. Equipment that can handle significant loads ensures that your facility runs smoothly.

Efficiency plays a vital role in reducing operational costs. High-efficiency machines not only save energy but also minimize waste generation. This results in lower disposal fees and environmental impact.

Consider the specific needs of your facility when evaluating capacity. Factors such as the type of sludge, moisture content, and desired dryness levels will influence your choice of equipment.

Look for models that offer adjustable settings to optimize performance based on varying conditions. This flexibility can lead to better resource management over time.

Investing in equipment with both high capacity and efficiency leads to improved productivity while supporting sustainable practices within wastewater treatment processes.

B. Technology and Innovation

When considering sludge dewatering equipment, technology and innovation play pivotal roles. Advancements in this field have transformed how industries manage waste.

Modern systems often incorporate automation features that enhance efficiency. These automated processes minimize human intervention, leading to more consistent results. They also reduce the risk of operator error, ensuring better compliance with environmental regulations.

Emerging technologies like membrane filtration and centrifugation are game-changers. Membrane systems provide high solid-liquid separation rates while maintaining a low footprint. Centrifuges offer rapid processing times for various sludge types.

Moreover, smart sensors and IoT connectivity enable real-time monitoring of operations. This data-driven approach helps optimize performance and predict maintenance needs before issues arise.

Investing in cutting-edge technology not only boosts productivity but can also lead to significant cost savings over time. Keeping an eye on innovations ensures your equipment remains competitive in an evolving market.

C. Maintenance and Operating Costs

When considering sludge dewatering equipment, maintenance and operating costs play a crucial role. The initial investment is just one part of the equation. Ongoing expenses can significantly impact your budget over time.

First, think about the frequency of maintenance required. Some systems demand regular servicing to ensure optimal performance. Others might be more forgiving but could incur higher operational costs due to inefficiency.

Energy consumption is another vital aspect. Advanced technology often comes with lower energy requirements, making it essential to weigh upfront costs against long-term savings.

Don’t overlook spare parts and repair expenses either. Choosing a manufacturer known for reliability can minimize unforeseen breakdowns and associated costs.

Consider labor needs for operation and maintenance tasks. Automation equipment may reduce the need for manual intervention, streamlining operations while keeping personnel expenditures in check.

D. Environmental Impact

When selecting sludge dewatering equipment, the environmental impact is a crucial factor. Efficient systems reduce water consumption and minimize waste production. This contributes to a smaller carbon footprint.

Modern technologies often utilize energy-efficient processes. Innovations in automation equipment enhance performance while lowering resource usage. These advancements not only support sustainability efforts but also comply with regulatory standards.

Moreover, consider how the discharge from dewatered sludge affects surrounding ecosystems. Equipment that safely treats and converts sludge into reusable materials can significantly benefit local environments.

Choosing environmentally friendly options reflects corporate responsibility. It demonstrates commitment to sustainable practices, appealing to both consumers and stakeholders alike. In an era where eco-consciousness matters more than ever, your choice of equipment plays a vital role in promoting ecological balance.

Top Rated Sludge Dewatering Equipment Brands

When it comes to sludge dewatering equipment, several brands stand out due to their innovation and reliability. Each brand offers unique features tailored for various industrial needs.

Geotube is renowned for its cost-effective solutions that utilize high-strength geotextiles. Their systems are perfect for large-scale projects requiring significant volume handling.

Then there’s Alfa Laval, known for its cutting-edge centrifuge technology. This brand excels in efficiency and energy savings, making it a favorite among environmentally conscious companies.

Another noteworthy mention is Andritz. They specialize in belt presses that provide excellent cake dryness and minimal polymer consumption. Their equipment is ideal for municipalities seeking sustainable practices.

The SLUDGE SQUEEZER by Duperon combines simplicity with effectiveness. It’s user-friendly and minimizes maintenance requirements while maximizing performance in smaller operations.

These brands exemplify quality and innovation in sludge dewatering equipment, catering to diverse operational needs across industries.

Case Studies: Successful Implementation of Sludge Dewatering Equipment

A municipal wastewater treatment facility in Texas faced challenges with excess sludge management. By integrating advanced sludge dewatering equipment, they achieved a 40% reduction in disposal costs. The system utilized centrifuges that maximized water removal efficiency.

In another instance, a food processing plant struggled with high organic content in its waste. They opted for belt filter presses to handle the thick sludge effectively. This choice not only streamlined their operations but also improved compliance with environmental regulations.

A mining company in Australia implemented screw press technology to deal with tailings management. It resulted in enhanced recovery of valuable resources and minimized land usage for waste storage.

These case studies highlight how tailored solutions can transform sludge handling processes across various industries, showcasing the versatility of modern dewatering technologies.

Common Challenges and Solutions for Sludge Dewatering

Sludge dewatering presents several challenges that operators must navigate. One common issue is the variability in sludge characteristics. Different sources produce sludge with varying compositions, impacting dewatering effectiveness.

Another challenge is managing the thickening process. If not done correctly, it can lead to increased chemical costs and operational inefficiencies.

Equipment malfunctions also pose significant hurdles. Breakdowns can halt production, leading to costly delays and maintenance expenses.

To tackle these issues, implementing automation equipment enhances monitoring and control during the dewatering process. This technology helps predict system performance based on real-time data.

Regular training for staff ensures they are equipped to handle unexpected problems swiftly. Additionally, routine maintenance checks keep machinery running smoothly, minimizing downtime and service interruptions.

Adopting a flexible approach allows for adjustments based on specific sludge types while optimizing overall efficiency in operations.

FQAs

When considering sludge dewatering equipment, you might have several questions. Here are some common inquiries.

What is the lifespan of sludge dewatering equipment? Longevity varies by model and usage but typically ranges from 10 to 20 years with proper care.

How much maintenance do these systems require? Regular inspections and routine cleaning are essential. Maintenance costs can vary based on technology used.

Can automation be integrated into existing systems? Yes, many modern machines support upgrades for better efficiency and control.

What types of materials can be processed? Most units handle a variety of sludges, including municipal wastewater and industrial byproducts.

Is training necessary for operators? Training ensures efficient use and safety compliance. Many manufacturers offer comprehensive guides or on-site training sessions.

Understanding these aspects will help you make an informed decision when investing in this critical equipment.

Conclusion

When it comes to selecting sludge dewatering equipment, careful consideration is essential. The right choice can greatly enhance operational efficiency and reduce costs in the long run. With various types of equipment available, understanding the specific needs of your facility will guide you toward the best solution.

The importance of capacity and efficiency cannot be overstated; these factors directly impact productivity. Embracing technology and innovation also plays a crucial role in staying competitive in today’s market. Additionally, keep an eye on maintenance and operating costs as they contribute significantly to overall expenses.

Environmental considerations are increasingly vital as regulations tighten around waste management practices. Choosing eco-friendly options not only ensures compliance but can improve public perception about your operations.

Recognizing top-rated brands that specialize in sludge dewatering equipment can help narrow down choices based on reputation and reliability. Real-world case studies reveal how successful implementation leads to improved performance outcomes across diverse industries.

Understanding common challenges associated with sludge dewatering allows operators to proactively seek solutions that optimize their processes further. As this field continues evolving with automation equipment advances, staying informed is key for effective decision-making.

Selecting the ideal sludge dewatering system requires diligence but pays off by streamlining operations while promoting sustainability goals within your organization.