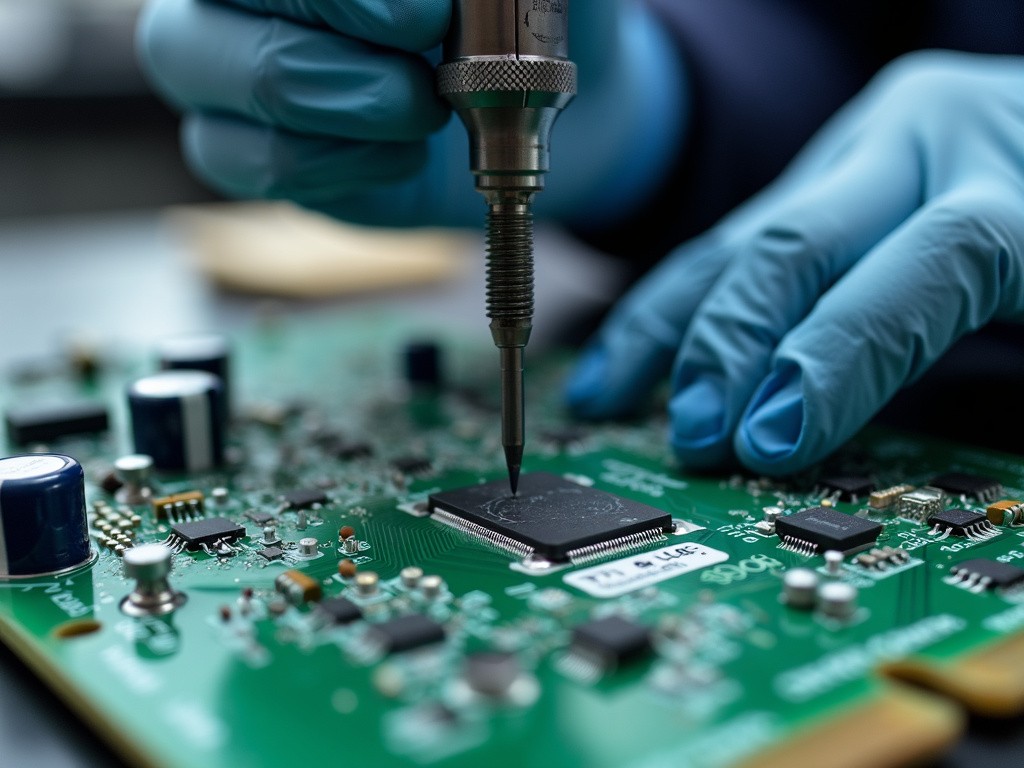

Custom circuit board assembly is becoming increasingly popular in industries such as electronics, automotive, healthcare, and consumer products. Whether you’re creating a new product or enhancing an existing one, custom circuit boards offer a wide range of advantages that can significantly improve performance, functionality, and design. This article explores the benefits of custom circuit board assembly, highlighting why more companies are choosing this tailored approach over pre-made solutions.

1. Tailored to Your Specific Needs

One of the main benefits of custom circuit board assembly is that the circuit boards are designed to meet your exact requirements. Unlike generic boards that may come with unnecessary components or features, custom boards are created to fit the specific needs of your project. This means you can decide on the size, shape, layout, and components that perfectly align with your product’s design.

For example, a custom circuit board might be necessary for a medical device that requires specialized sensors or for a compact gadget where space is limited. Customization ensures that the circuit board performs the desired functions without any unnecessary features, which improves both performance and efficiency.

2. Improved Performance

Because custom circuit boards are designed specifically for their intended use, they often result in better performance compared to off-the-shelf options. Engineers can optimize the layout and configuration of the components, ensuring that the board runs as efficiently as possible. The customization process allows you to address specific performance needs such as reducing electrical noise, improving heat dissipation, or optimizing power consumption.

For example, in a high-performance device, you can design a custom PCB to minimize signal interference or maximize processing speed, ensuring that the final product delivers top-notch performance.

3. Cost Efficiency Over Time

At first glance, custom circuit boards might seem more expensive than pre-made ones. However, they can actually save you money in the long run. Custom PCBs eliminate the need for unnecessary components, which reduces material costs. They also lead to fewer issues during production, minimizing the likelihood of errors and the need for costly rework.

Additionally, custom circuit boards often offer better durability and longevity, which reduces the need for repairs or replacements. If a generic circuit board fails prematurely or doesn’t quite fit the specifications, you could end up spending more time and money troubleshooting or modifying it to suit your needs.

4. Space Optimization

Another significant advantage of custom circuit board assembly is the ability to design the board with space efficiency in mind. In many modern devices, especially consumer electronics like smartphones and wearable tech, space is at a premium. Custom PCBs can be made smaller, more compact, and perfectly shaped to fit into tight spaces, unlike off-the-shelf boards that may be bulky or irregularly shaped.

By optimizing the use of space on the board, engineers can also ensure that there’s better airflow and heat dissipation, further enhancing the product’s reliability and performance. This is particularly important for products where internal overheating can be an issue.

5. Enhanced Reliability and Quality Control

Custom circuit boards undergo rigorous design, testing, and quality control processes tailored to the specific application they are intended for. This ensures higher reliability, which is critical for products that require long-term operation, such as medical devices, automotive systems, and industrial equipment.

With custom circuit board assembly, manufacturers can control the quality at each step of the production process, from choosing the best materials to ensuring precise placement of components. The result is a product with a higher degree of reliability, fewer defects, and better overall performance.

6. Flexibility in Design

With custom circuit board assembly, you’re not limited by the constraints of generic designs. You have the flexibility to include the exact components and features you need, while leaving out those that you don’t. This allows for greater creativity and innovation, giving you the freedom to design cutting-edge products with unique functionality.

For instance, if you’re designing a product that needs to adapt to future upgrades, a custom PCB can be built with expansion in mind. Whether you need additional connectors, extra space for components, or specific routing for signals, a custom circuit board can meet those requirements.

7. Faster Prototyping and Product Development

Custom circuit boards allow for rapid prototyping, which is essential in the fast-paced world of product development. Rather than being restricted by standard circuit board designs, you can work directly with engineers to create, test, and refine your own design. This accelerates the entire product development cycle, allowing you to bring your product to market faster.

Additionally, custom PCBs enable quicker modifications during the testing phase. If any issues arise, they can be addressed directly in the design, resulting in a quicker turnaround time for revisions.

8. Compatibility with Advanced Technologies

As technology continues to advance, the need for custom solutions has become more apparent. Custom circuit board assembly offers the flexibility needed to incorporate the latest technological advancements such as multi-layered PCBs, flexible circuit boards, and high-density interconnect (HDI) technology.

For instance, flexible PCBs are commonly used in applications where the board needs to bend or fold, such as wearable devices or medical implants. These advanced features are rarely available in off-the-shelf circuit boards, making custom assembly the ideal solution for cutting-edge products.

9. Sustainability and Energy Efficiency

Custom circuit boards allow for better control over energy consumption. By selecting only the components needed and optimizing the board’s design, manufacturers can reduce power consumption, which is a key benefit in today’s energy-conscious world. This not only makes products more eco-friendly but also reduces operational costs, particularly for battery-powered devices.

Moreover, custom PCBs can be designed with sustainability in mind, using materials that are more environmentally friendly and ensuring that the board is as energy-efficient as possible.

10. Support and Collaboration with Experts

Working with a custom circuit board assembly service gives you access to expert engineers and designers who can provide guidance and support throughout the process. This collaborative effort ensures that the final product not only meets your specifications but is also optimized for performance and manufacturability.

These experts can help with everything from component selection to layout optimization, ensuring that your design meets both technical and cost objectives. With their support, you can avoid common pitfalls, such as poor heat management or electrical interference, which can significantly impact the performance of your device.

Conclusion

Custom circuit board assembly offers numerous benefits for businesses looking to create innovative, high-performance, and cost-effective products. From tailored design and improved performance to better space optimization and long-term cost savings, custom PCBs are the ideal solution for projects that demand precision and efficiency. By partnering with experienced professionals like OurPCB, companies can produce circuit boards that not only meet but exceed expectations. Whether you’re developing a medical device, a new piece of consumer electronics, or an industrial system, custom circuit board assembly will give you the competitive edge you need.