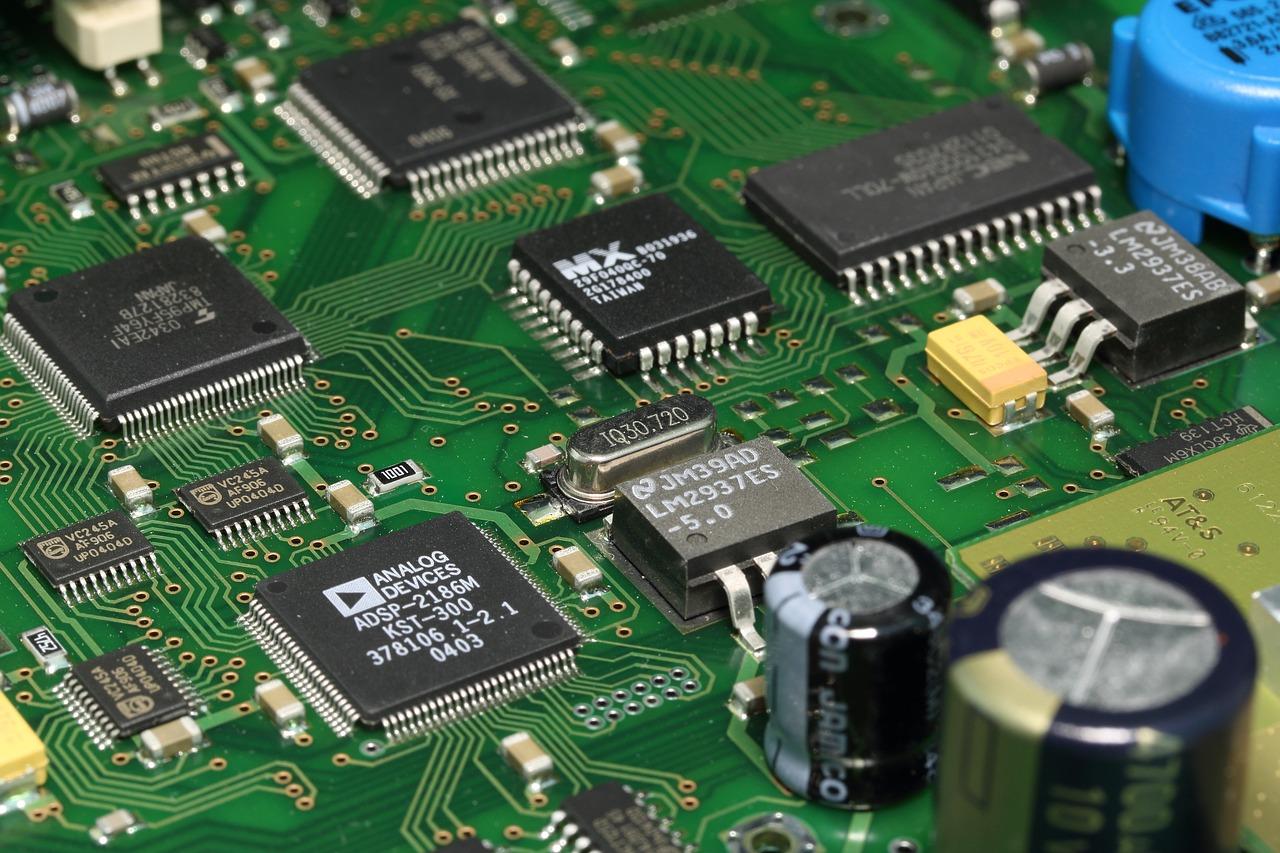

Printed Circuit Boards play a crucial role in everything from smartphones to medical devices. When planning a new electronics project, obtaining an accurate PCB quotation is essential. An accurate quote helps ensure that the project stays within budget and on schedule, avoiding unexpected costs and delays.

Several key factors influence PCB quotations. These include material costs, design complexity, quantity, and lead time. Understanding these factors can help in making informed decisions and optimizing the design for cost-effectiveness.

In this article, we will explore the intricacies of PCB quotations. By understanding these elements, you can navigate the quoting process with confidence and ensure that your project proceeds smoothly.

Understanding PCB Quotation

A PCB quotation is an estimate provided by a manufacturer detailing the costs associated with producing a PCB assembly. This estimate includes various components such as material costs, labor, and any additional services required for assembly and testing.

Accurate PCB quotations are crucial for budgeting and planning, as they provide a clear picture of the financial requirements and help in avoiding unforeseen expenses.

Factors Affecting PCB Quotations

- Material Costs: The type of materials used in PCB production significantly impacts the overall cost. Common materials include FR4 (a composite of glass fiber and epoxy resin), which is standard for most PCBs, and more specialized materials like Rogers or aluminum, used for high-frequency or high-power applications. The choice of materials affects not only the cost but also the performance and durability of the PCB.

- Design Complexity: The complexity of the PCB design is another critical factor. Simple single-layer boards are cheaper to produce than multi-layer boards with intricate designs. Factors such as the number of layers, the density of the components, the width of the traces, and the type of vias (through-hole, blind, or buried) all contribute to the complexity and cost.

- Quantity: The number of PCBs ordered plays a significant role in the pricing. Manufacturers often offer discounts for bulk orders due to economies of scale. Small production runs typically incur higher costs per unit compared to large-volume orders.

- Lead Time: The time frame for delivering the PCBs can also influence the quote. Rush orders requiring expedited manufacturing and shipping are more expensive than standard delivery schedules. Planning ahead and allowing for standard lead times can help in reducing costs.

Understanding these factors can aid in making strategic decisions during the design and planning stages, ultimately leading to cost savings and efficient project execution.

PCB Instant Quote: What You Need to Know

PCB instant quote systems are online tools provided by many PCB manufacturers. These tools allow customers to input their design specifications and receive an immediate estimate of the production costs. This automated process simplifies the quoting procedure, making it quicker and more accessible.

Benefits of Using Instant Quotes

- Time Efficiency: One of the primary advantages of PCB instant quotes is the time saved. Traditional quotation processes can take days or even weeks, as they involve back-and-forth communication between the customer and the manufacturer. Instant quote systems, on the other hand, provide immediate feedback, allowing for faster decision-making and project initiation.

- Cost Transparency: Instant quote systems offer transparency in pricing. Customers can see a detailed breakdown of costs based on their input specifications. This transparency helps in understanding how different factors, such as material choices or design complexity, affect the overall price. It also enables customers to make adjustments to their designs to stay within budget.

Key Considerations

- Input Requirements: To get an accurate instant quote, customers need to provide detailed information about their PCB design. This includes dimensions, number of layers, type of materials, surface finish, and any special requirements. Accurate input ensures that the quote reflects the true cost of production.

- Accuracy and Reliability: While instant quote systems are convenient, it’s important to ensure that the provided information is accurate. Discrepancies between the input specifications and the actual design can lead to variations in the final cost. It’s advisable to double-check the input details and, if necessary, consult with the manufacturer to clarify any uncertainties.

By leveraging PCB instant quote systems, designers and engineers can streamline the quoting process, gain clear insights into cost structures, and make informed decisions that align with their project goals and budget constraints.

Factors Influencing PCB Assembly Quotes

When it comes to PCB assembly, several key components influence the overall quote. Understanding these components can help you budget effectively and optimize costs.

- Component Sourcing: This involves procuring the electronic components that will be mounted on the PCB. The cost can vary based on the type, quality, and availability of the components. Specialty or rare components can be more expensive and may also have longer lead times. It’s often beneficial to source components from reputable suppliers to ensure quality and reliability.

- Assembly Labor: The labor cost includes the work required to place and solder components onto the PCB. The complexity of the assembly, such as the number of components and the types of soldering techniques required (e.g., surface-mount technology (SMT) or through-hole technology), directly impacts the labor cost. Automated assembly lines can reduce labor costs, especially for high-volume production runs.

- Testing and Inspection: Ensuring the assembled PCBs work correctly is crucial. This process includes various testing methods like in-circuit testing (ICT), functional testing, and automated optical inspection (AOI). These steps help identify defects and ensure the quality of the final product. Testing and inspection add to the overall cost but are necessary to guarantee reliability and performance.

Cost-Saving Tips for PCB Assembly

- Bulk Ordering: Ordering components in bulk can significantly reduce costs due to economies of scale. Larger orders often attract discounts from suppliers, which can lead to substantial savings, especially for high-volume production runs.

- Standardizing Components: Using standard, widely available components rather than custom or specialized ones can help keep costs down. Standard components are typically cheaper and more readily available, reducing both procurement costs and lead times.

PCB Fabrication Quote: Key Elements

PCB fabrication involves creating a physical board that supports and connects the electronic components. The process includes several stages, such as creating the board layout, transferring the design to the board, etching the circuit patterns, drilling holes, and applying surface finishes. Each of these steps has associated costs that contribute to the overall fabrication quote.

Essential Elements in a PCB Fabrication Quote

- Material Selection: The choice of materials is one of the most significant factors in the cost of PCB fabrication. Common materials include FR4 (fiberglass epoxy), which is widely used due to its good balance of performance and cost. Other materials like Rogers (for high-frequency applications) or metal-core PCBs (for high-power applications) can be more expensive but necessary for specific performance requirements.

- Board Complexity: The complexity of the board design greatly influences the cost. This includes the number of layers in the board, the density and width of the traces, and the types of vias (through-hole, blind, or buried). Multi-layer boards, which are needed for more complex circuits, are more expensive to fabricate than single-layer boards.

- Special Requirements: Additional features such as impedance control, high-density interconnects (HDI), and specific surface finishes (e.g., ENIG, HASL, or OSP) can add to the fabrication costs. These requirements often arise from the need to meet specific performance or durability criteria.

How to Optimize Fabrication Costs

- Choosing Appropriate Materials: Selecting materials that balance cost and performance for your specific application can help reduce costs. For instance, using standard FR4 material instead of a more expensive alternative unless absolutely necessary can keep costs down.

- Simplifying Design: Reducing the number of layers and minimizing the use of specialized features where possible can lower fabrication costs. Simplified designs are not only cheaper to produce but also easier to assemble and test.

Understanding PCB Manufacturing Quotes

PCB manufacturing encompasses the entire process of producing a PCB from the initial design to the final product. This includes prototyping, fabrication, assembly, and testing. Each stage has associated costs that are reflected in the overall manufacturing quote.

Components of a PCB Manufacturing Quote

- Prototyping Costs: Before full-scale production, creating a prototype is essential to test the design and functionality. Prototyping costs include the initial setup, material costs, and labor for producing a small batch of boards. Prototypes are typically more expensive per unit due to the lower volume and higher setup costs.

- Full Production Costs: Once the prototype is validated, the project moves to full-scale production. The costs here are more distributed due to the higher volume. Full production costs include material procurement, fabrication, assembly, and testing. The unit cost typically decreases with higher production volumes due to economies of scale.

- Additional Services: Services such as stencil production (used for applying solder paste) and surface finishing (e.g., gold plating solder masking) are additional costs that can be included in the quote. These services are often necessary for ensuring the quality and performance of the final product.

Tips for Reducing Manufacturing Costs

- Efficient Prototyping: Streamlining the prototyping phase by minimizing design changes and using efficient production methods can reduce costs. Working closely with the manufacturer during this stage can help identify cost-saving opportunities.

- Volume Production Benefits: Ordering larger production runs can significantly reduce the per-unit cost. Manufacturers often offer discounts for bulk orders, and the fixed costs (like setup and tooling) are spread over a larger number of units, lowering the overall cost.

By understanding the components of PCB assembly, fabrication, and manufacturing quotes, you can make informed decisions to optimize costs and ensure the success of your project.

Getting an Accurate PCB Quotation

Obtaining an accurate PCB quotation is critical for budgeting and planning your project effectively. Here are key steps to ensure you get a precise quote:

- Providing Detailed Design Files (Gerber Files): Gerber files are essential in PCB manufacturing as they contain all the necessary information about your design, including the layout, layers, and drill data. Ensuring these files are detailed and correctly formatted helps the manufacturer understand your exact requirements, reducing the chances of errors and miscommunications.

- Clear Specifications and Requirements: Alongside Gerber files, providing a comprehensive list of specifications and requirements is crucial. This includes details about materials, board thickness, surface finish, solder mask color, and any special features like impedance control or HDI. The more precise your specifications, the more accurate the quote will be.

- Importance of Communication with the Supplier: Effective communication with your supplier is vital. Discussing your project in detail, asking questions, and clarifying any uncertainties can prevent misunderstandings. Maintaining open lines of communication ensures that the supplier fully grasps your needs and can provide a tailored quote.

- Common Pitfalls to Avoid: Common mistakes that can lead to inaccurate quotes include providing incomplete design files, omitting crucial specifications, and failing to communicate special requirements. Double-checking all provided information and maintaining thorough communication can help avoid these pitfalls.

Comparing PCB Quotes: What to Look For

When comparing PCB quotes from different suppliers, consider the following key factors to make an informed decision:

- Price: While cost is a significant factor, it should not be the only one. Compare the prices while also considering what is included in the quote (e.g., material quality, additional services).

- Lead Time: The time required to deliver the PCBs is crucial, especially if you have tight deadlines. Ensure that the quoted lead time meets your project schedule.

- Quality: Look into the quality of the PCBs the supplier produces. Reading reviews, asking for samples, and checking certifications can provide insights into the supplier’s quality standards.

- Supplier Reputation: A supplier’s reputation can tell you a lot about their reliability and service quality. Research the supplier’s history, customer reviews, and industry reputation to gauge their trustworthiness.

Obtaining an accurate PCB quotation is essential for the success of your electronics project. By providing detailed design files and specifications, maintaining clear communication with your supplier, and avoiding common pitfalls, you can ensure an accurate quote.

When comparing quotes, consider price, lead time, quality, and supplier reputation to make an informed decision. Ultimately, choosing the right PCB supplier is crucial for meeting your project’s budget and timeline while ensuring high-quality results.