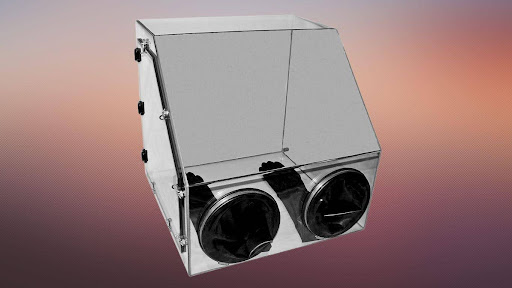

Lab glove boxes are fundamental instruments for different logical and modern applications, giving a controlled climate to dealing with delicate materials. In any case, similar to any gear, they can experience gives that might upset their usefulness. Understanding normal issues and their investigating techniques is critical for keeping up with the productivity and wellbeing of glove boxes.

1. Holes and Defilement

Issue: One of the most well-known issues with lab glove boxes is the event of breaks, which can prompt tainting of the controlled climate.

Investigating:

Normal Examination: Lead routine keeps an eye on seals, gaskets, and gloves for any indications of wear, tears, or inappropriate fitting. Supplant harmed parts right away.

Pressure Tests: Perform ordinary tension rot tests to recognize spills. An unexpected drop in pressure shows a release that should be tended to.

Seal Support: Guarantee that all seals and gaskets are appropriately greased up and liberated from trash. Utilize proper cleaning specialists and oils suggested for lab glove box upkeep.

2. Glove Debasement

Issue: The gloves of a glove box are inclined to mileage because of consistent use, openness to synthetic compounds, and actual pressure.

Investigating:

Continuous Examinations: Consistently assess gloves for penetrates, tears, and indications of debasement. Carry out a timetable for supplanting gloves in light of their use and material similarity.

Appropriate Utilization: Train clients on the right strategies for taking care of and utilizing gloves to limit pointless pressure and harm.

Material Choice: Use gloves produced using materials appropriate for the synthetic substances and cycles being taken care of inside the glove box.

3. Ill-advised Climate Control

Issue: Keeping up with the right air inside a glove box, whether it’s latent, vacuum, or controlled stickiness, is basic. Issues with air control can think twice about or processes.

Investigating:

Sensor Adjustment: Consistently align sensors and observing gear to guarantee exact readings of temperature, moistness, and gas focuses.

Spill Location: Likewise with general breaks, check for any breaks that could permit outside air or dampness to enter the glove box.

Gas Cleansing: Guarantee that the gas cleansing framework is working accurately. Supplant channels and purifiers on a case by case basis to keep up with the virtue of the inward environment.

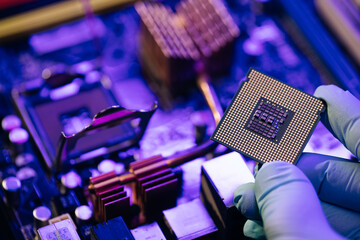

4. Electrical and Mechanical Disappointments

Issue: Electrical and mechanical parts, for example, lighting, vacuum siphons, and gas valves, can bomb after some time.

Investigating:

Routine Support: Follow the producer’s suggested upkeep plan for all electrical and mechanical parts. Routinely test these frameworks to guarantee they are working appropriately.

Spare Parts Stock: Keep a stock of fundamental extra parts to work with speedy substitutions when parts fizzle.

Proficient Overhauling: Connect with qualified professionals for complex fixes and adjusting to forestall further harm and guarantee appropriate usefulness.

5. Client Blunder

Issue: Human blunder is a huge calculate numerous glove box issues, including ill-advised taking care of, wrong activity, and lacking support.

Investigating:

Exhaustive Preparation: Give careful preparation to all clients on the right activity and upkeep of the glove box. Guarantee that they figure out the significance of following conventions.

Clear Documentation: Keep up with definite functional manuals and investigating guides available to all clients.

Normal Reviews: Direct ordinary reviews of glove box use and upkeep practices to distinguish and address any deviations from standard methodology.

6. Buildup and Mugginess Control

Issue: Buildup can shape inside a glove box, particularly while managing temperature changes or damp circumstances, prompting dampness related issues.

Investigating:

Dehumidification: Use dehumidifiers or desiccants to control moistness levels inside the glove box. Consistently supplant or recover desiccants depending on the situation.

Temperature Control: Keep up with stable temperatures inside the glove box to forestall buildup. Protect the glove box if important to limit temperature varieties.

Dampness Checking: Introduce stickiness sensors to constantly screen dampness levels and make restorative moves quickly.

7. Perceivability Issues

Issue: After some time, the perceivability through the glove box’s survey window can weaken because of scratches, misting, or synthetic stores.

Investigating:

Ordinary Cleaning: Clean the survey window routinely with suitable, non-grating cleaners. Try not to utilize unforgiving synthetic compounds that could harm the surface.

Defensive Movies: Consider applying defensive movies or coatings to the window to forestall scratches and compound stores.

Substitution: In the event that the perceivability is seriously compromised, supplant the review window with another one to guarantee clear perception of the inner climate.

End

Keeping a lab glove box requires industrious tender loving care and a proactive way to deal with investigating normal issues. Normal examinations, legitimate upkeep, and careful preparation are fundamental to guarantee the glove confine stays a dependable instrument a controlled climate. By resolving issues immediately and successfully, clients can expand the life expectancy of their glove box and keep up with the trustworthiness of their examinations and cycles.