Potentiometers play a pivotal role in controlling various parameters such as voltage, current, and resistance in the realm of electronic components. Among the diverse types of potentiometers, multi-turn potentiometers and single-turn potentiometers are prominent for their specific functionalities and applications. This article delves into the intricacies of these two types of potentiometers, highlighting their differences, applications, and advantages.

What is a Potentiometer?

A potentiometer is an adjustable resistor used to control electrical devices. It comprises a resistive element, a sliding contact (wiper), and three terminals. By adjusting the position of the wiper along the resistive element, the resistance can be varied, allowing for precise control over the electrical signal.

Single Turn Potentiometers

Single turn potentiometers, as the name suggests, allow the wiper to traverse the entire resistive element in a single 360-degree rotation. These potentiometers are commonly used in applications requiring quick adjustments and where high precision is not a primary concern.

Features of Single Turn Potentiometers

- Simplicity: Single turn potentiometers are straightforward in design, making them easy to use and install.

- Speed of Adjustment: They allow for rapid adjustments since the full resistance range can be achieved with one full turn.

- Compact Size: Their simple design often results in a more compact form factor, suitable for applications with limited space.

Applications of Single Turn Potentiometers

- Volume Controls: Commonly used in audio equipment to adjust volume levels.

- Lighting Dimmers: Utilized in lighting systems to control light intensity.

- Instrumentation: Employed in various instruments for fine-tuning and calibration.

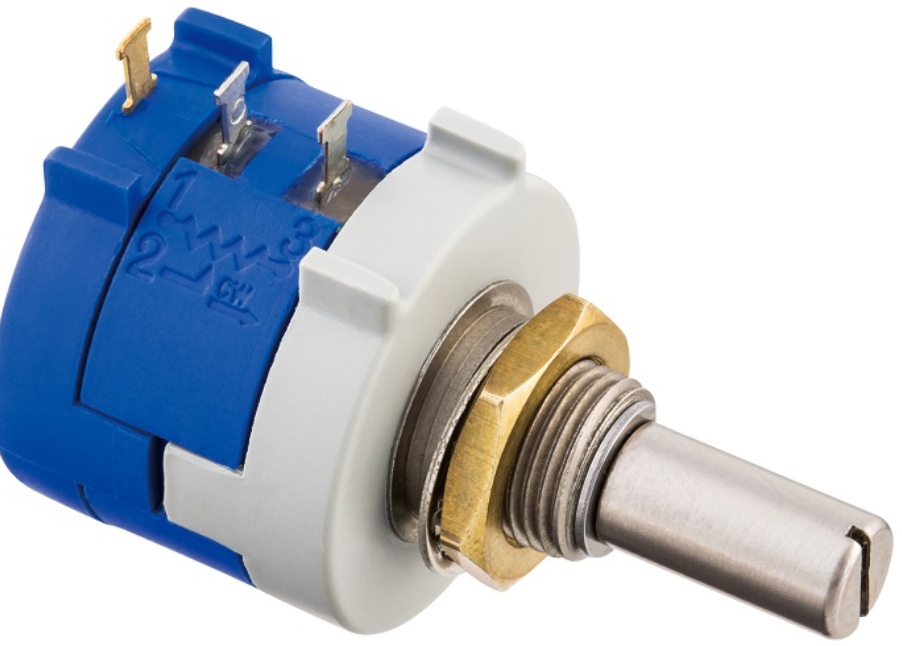

Multi-Turn Potentiometers

Multi-turn potentiometers, on the other hand, require multiple wiper rotations to traverse the entire resistive element. They are designed for applications demanding high precision and fine adjustments.

Features of Multi-Turn Potentiometers

- Precision: The multiple turns allow for finer control and higher resolution adjustments.

- Stability: Due to the finer adjustments, multi-turn potentiometers offer more stable and repeatable settings.

- Durability: Often built to withstand repeated adjustments without significant wear.

Applications of Multi-Turn Potentiometers

- Precision Calibration: Used in laboratory equipment and test instruments where precise control is paramount.

- Servo Mechanisms: Employed in servo systems to fine-tune motor positions.

- Industrial Controls: Used in industrial automation for precise control of machinery.

Differences Between Single Turn and Multi-Turn Potentiometers

- Adjustment Range: Single turn potentiometers cover the full resistance range in one turn, while multi-turn potentiometers require multiple turns.

- Precision: Multi-turn potentiometers offer higher precision and finer control than single turn potentiometers.

- Application: Single turn potentiometers are suitable for quick adjustments, whereas multi-turn potentiometers are ideal for applications requiring meticulous calibration.

Choosing the Right Potentiometer

The choice between a multi-turn potentiometer and a single turn potentiometer depends on the application’s specific requirements. If rapid adjustments and simplicity are needed, a single turn potentiometer is the ideal choice. A multi-turn potentiometer is more suitable for applications demanding precise control and fine adjustments.

Conclusion

In conclusion, understanding the differences between multi-turn potentiometers and single-turn potentiometers is crucial for selecting the right component for your application. While single-turn potentiometers are perfect for quick and simple adjustments, multi-turn potentiometers excel in applications requiring precision and stability. Brands like ETI Systems and Digikey offer a wide range of potentiometers to cater to diverse needs, ensuring that you find the right fit for your project.

By carefully considering your application’s specific needs and the unique features of each type of potentiometer, you can make an informed decision that enhances the performance and reliability of your electronic devices.