Post Preview

Table of Contents

- What is Direct-to-Film (DTF) Printing?

- Advantages of DTF Printing

- DTF vs. Other Printing Methods

- Real-World Applications

- Steps to Start Using DTF Printing

- Recent Developments in DTF Printing

- The Future of DTF Printing

What is Direct-to-Film (DTF) Printing?

Direct-to-film (DTF) printing is an innovative technique that brings a new level of flexibility and vibrant color to custom apparel. By utilizing a DTF printer, designs are printed onto a unique film, which is then heat transferred onto a wide range of fabrics. This method’s ability to deliver intricate and high-quality prints sets it apart in the textile printing industry. The process starts with creating a digital design, which is then printed onto PET film using a specialized DTF printer. Once the design is printed, it’s coated with an adhesive powder and cured. The final step is transferring the design onto the fabric using a heat press, achieving both durability and vibrancy that are crucial for custom apparel.

Advantages of DTF Printing

DTF printing offers several compelling advantages that make it a popular choice for custom apparel creators. Foremost among these is its exceptional detail and color vibrancy. The ability to print complex and colorful designs with remarkable accuracy ensures that each print captures the intended aesthetic down to the finest detail. Additionally, DTF printing is known for its durability. The combination of high-quality inks and robust transfer films results in prints that withstand repeated washing and heavy use without significant fading or cracking. This makes DTF printing not only an aesthetically appealing option but also a practical one for everyday wear. Another benefit is cost-effectiveness. Compared to other methods, DTF requires fewer materials, and the process itself is less time-consuming, making it a more economical choice for both small and large printing operations. For those looking to experiment with new designs or cater to custom orders, DTF provides an affordable solution that doesn’t compromise on quality.

DTF vs. Other Printing Methods

It’s essential to weigh the distinct advantages that each printing technique offers when choosing between DTF printing and alternatives like screen printing or Direct-to-Garment (DTG) printing. While DTG is excellent for high-resolution pictures on cotton fabrics and screen printing is suitable for large orders, DTF offers flexibility. Cotton, polyester, and blended textiles are just a few of the many materials that may be printed on using DTF technology. The simplicity of the procedure, which is less complicated and takes less setup time than screen printing, adds even more adaptability to this. Due to these benefits, DTF is a desirable choice for companies wishing to increase their printing capacity without having to make a sizable additional financial commitment.

Real-World Applications

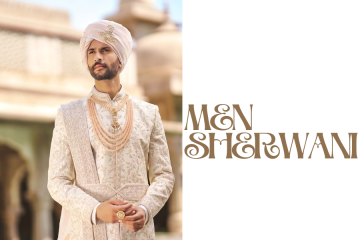

One of the most exciting aspects of DTF printing is its wide range of applications. In the fashion industry, it enables designers to create unique, personalized garments that stand out in a crowded market. Retailers can offer custom t-shirts, hoodies, and accessories that reflect the latest trends or cater to niche audiences. Promotional items are another area where DTF printing excels. Companies can use this technology to produce branded merchandise such as bags, hats, and aprons, helping to increase brand visibility and customer engagement. The flexibility of DTF printing makes it an excellent choice for small businesses and startups looking to offer high-quality products.

Steps to Start Using DTF Printing

- Invest in a reliable DTF printing machine: Choose a machine that suits your production needs and fits within your budget. Research various models to find one that offers the best balance of quality and cost.

- Select high-quality films and inks: The quality of your materials will directly impact the final product, so it’s essential to choose carefully. Look for suppliers with a reputation for consistency and reliability.

- Understand the process: Familiarize yourself with the steps from design creation to the final heat transfer to ensure a smooth workflow. Practical training sessions or tutorials can be invaluable in mastering the intricacies of DTF printing.

- Test on different materials: Experiment with various fabric types to see how the prints hold up and make any necessary adjustments. This will help you identify the best combinations for different project needs.

- Market your custom apparel: Once you’re satisfied with your products, start promoting marketing channels target audience through various marketing channels. Utilize social media, online stores, and local events to showcase your unique offerings.

Recent Developments in DTF Printing

Recent technological developments have improved DTF printing’s capabilities even more. For example, printhead designs that have been improved have resulted in increased precision and faster manufacturing times. Users may now develop more realistic designs and manage color profiles more efficiently, thanks to upgrades in modern software. Moreover, DTF printing is now seen as a more sustainable choice thanks to the advancement of environmentally friendly inks and materials. The environmental effect has been dramatically decreased by these improvements, which is in line with the rising need for more environmentally friendly manufacturing techniques. As DTF technology continues to close the gap between outdated methods and contemporary specifications, the screen printing industry has taken notice of these developments.

The Future of DTF Printing

DTF printing appears to have a promising future. We could anticipate more advancements in efficiency, precision, and sustainability as technology develops. Large industries and small organizations alike will probably find DTF printing even more accessible as a result of the continuous push toward digital and automated operations. Additionally, DTF printing will be used much more frequently as personalized consumer goods become more and more popular. Because it can provide personalized items at a reasonable price and promptly, DTF is well-positioned to grow into a significant force in the print-on-demand market.