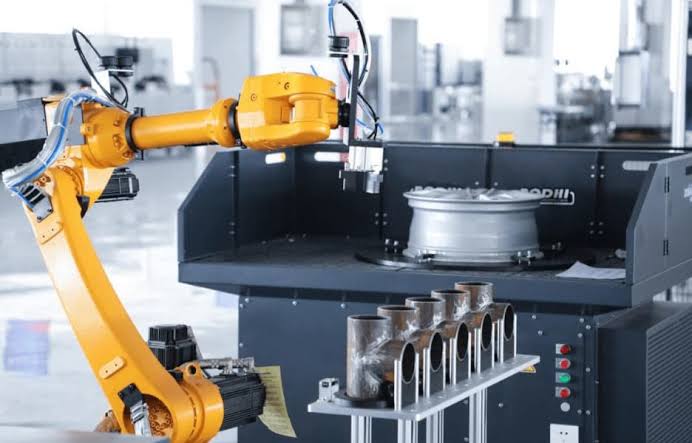

Aluminum die casting is a highly efficient and versatile manufacturing process used to produce complex metal components with high precision and durability. It involves injecting molten aluminum into a steel mold or die under high pressure, creating parts that are lightweight, strong, and resistant to corrosion. Aluminum Die Casting Services is widely used across various industries, including automotive, aerospace, electronics, and industrial machinery, due to its ability to produce intricate shapes with excellent dimensional accuracy.

In this article, we will explore the benefits of aluminum die casting, the services offered by leading aluminum die casting providers, and why this process is essential for modern manufacturing.

What is Aluminum Die Casting?

Aluminum die casting is a process where molten aluminum is injected into a mold cavity at high pressure. The aluminum quickly cools and solidifies to form the desired shape, after which the part is ejected from the mold. The die, typically made of steel, can be used repeatedly, making it ideal for high-volume production runs. This process allows manufacturers to create parts with intricate designs, tight tolerances, and smooth surface finishes.

Why Aluminum?

Aluminum is one of the most widely used materials in die casting due to its excellent properties:

- Lightweight: Aluminum is much lighter than steel, making it ideal for industries like automotive and aerospace, where weight reduction is critical for fuel efficiency and performance.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion, which is particularly valuable in harsh environments.

- Thermal and Electrical Conductivity: Aluminum’s high conductivity makes it ideal for heat sinks and electronic enclosures.

- Strength and Durability: Despite its light weight, aluminum offers excellent strength and durability, making it suitable for structural components.

Benefits of Aluminum Die Casting

Aluminum die casting offers several advantages that make it one of the most popular manufacturing methods for producing metal parts:

1. High Precision and Dimensional Accuracy

Aluminum die casting enables the production of parts with high precision and tight tolerances. This is especially important for industries where accuracy is critical, such as automotive and aerospace, where components must fit together perfectly and function reliably under stress.

2. Lightweight and Strong Parts

Aluminum’s lightweight nature combined with its strength makes it a preferred material for applications where reducing weight is essential, such as in the automotive industry. Die-cast aluminum parts offer the ideal balance of durability and weight reduction, improving fuel efficiency and overall performance.

3. Cost-Effective for High-Volume Production

Aluminum die casting is highly efficient, making it an economical choice for large production runs. Once the mold is created, the process can be repeated quickly and consistently, allowing for mass production of identical parts with minimal variation. This leads to significant cost savings over time, especially for industries requiring thousands or millions of units.

4. Complex Designs and Thin Walls

Aluminum die casting allows manufacturers to create parts with complex shapes, thin walls, and intricate details that would be difficult or impossible to achieve with other manufacturing processes. This design flexibility enables the production of lightweight components that still maintain their strength and functionality.

5. Smooth Surface Finishes

Die-cast aluminum parts often come out of the mold with a smooth surface finish, reducing the need for additional post-processing. This not only saves time but also reduces production costs. If desired, additional finishes such as painting, powder coating, or anodizing can be applied to enhance appearance and corrosion resistance.

6. Superior Corrosion Resistance

Aluminum’s natural corrosion resistance makes it ideal for applications exposed to moisture, chemicals, or extreme weather conditions. Components such as outdoor enclosures, automotive parts, and marine equipment benefit from aluminum’s ability to withstand harsh environments without deteriorating.

Common Applications of Aluminum Die Casting Services

Aluminum die casting is used in a wide range of industries to produce components that require high strength, durability, and precision. Some of the most common applications include:

1. Automotive Industry

Aluminum die casting is extensively used in the automotive sector for producing lightweight, high-strength parts such as engine blocks, transmission housings, brackets, and structural components. The ability to reduce the weight of vehicles while maintaining strength is critical for improving fuel efficiency and reducing emissions.

2. Aerospace and Defense

In aerospace and defense, weight is a major concern. Aluminum die-cast components are used in aircraft frames, engine components, and other critical parts to reduce overall weight while maintaining the strength needed to withstand extreme forces and environmental conditions.

3. Electronics and Telecommunications

Aluminum die casting is often used to manufacture electronic enclosures, heat sinks, and housings for telecommunications equipment. The excellent thermal conductivity of aluminum makes it ideal for managing heat generated by electronic components, ensuring that devices operate efficiently and without overheating.

4. Industrial Machinery

Aluminum die casting is used to produce components for industrial machinery and tools that require durability and high-performance under stress. These components include housings, pump parts, and motor covers, which benefit from aluminum’s strength and corrosion resistance.

5. Consumer Goods

Aluminum die casting is also prevalent in the manufacturing of consumer products such as kitchen appliances, furniture components, and sports equipment. The lightweight and aesthetic appeal of aluminum make it a preferred material for a variety of everyday products.

The Aluminum Die Casting Process: From Design to Production

1. Design and Tooling

The aluminum die casting process begins with the design of the part and the creation of the die (mold). The design phase is crucial as it determines the functionality, dimensions, and features of the part. The mold is made from high-strength steel and is designed to withstand repeated cycles of high-pressure casting.

2. Melting the Aluminum

Once the mold is ready, aluminum is heated in a furnace until it reaches its molten state. The molten aluminum is then injected into the mold under high pressure, filling the cavity and taking the shape of the mold.

3. Cooling and Ejection

After the molten aluminum has been injected, it cools and solidifies within the mold. Once the part has fully hardened, the mold is opened, and the part is ejected. This process can be repeated continuously, allowing for high-speed production.

4. Post-Processing

Depending on the application, the part may undergo additional processes such as trimming, polishing, or surface finishing to remove any excess material or imperfections. Coatings such as anodizing or powder coating may also be applied to enhance corrosion resistance or aesthetic appeal.

Conclusion

Aluminum die casting is a versatile and efficient manufacturing process that offers numerous benefits, including high precision, cost-effectiveness, and the ability to create complex designs. Whether you’re in the automotive, aerospace, electronics, or industrial sector, aluminum die casting services provide the strength, durability, and lightweight characteristics necessary for producing high-quality components.

By choosing aluminum die casting, companies can ensure reliable performance, reduce production costs, and maintain the flexibility to produce intricate designs with excellent surface finishes. For manufacturers seeking high-volume production with precision and efficiency, aluminum die casting is a smart and cost-effective solution.